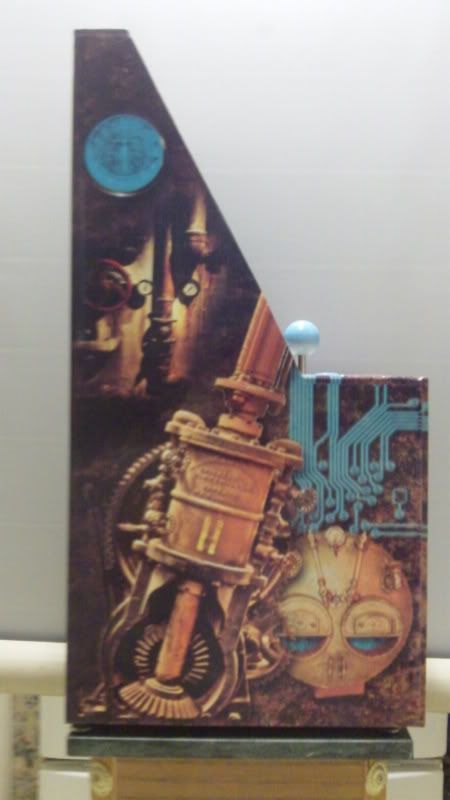

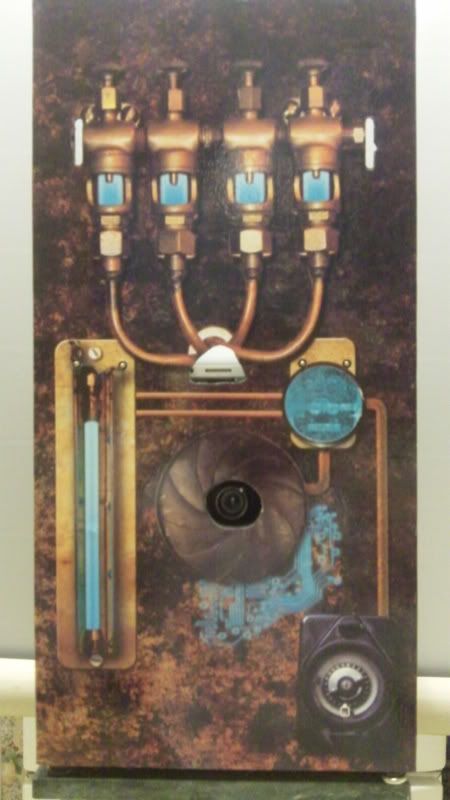

So I finally got around to getting some artwork for the iPad Arcade. I went with a vinyl wrap. The design and asthetic are my choosing but Mandy from Ugly Signs did the actual artwork. I think a little personality is exactly what this project needed.

You cant make it our in the picture but the dials on that last image read out 31337. Leave a comment and tell me what you think...

Friday, August 27, 2010

Thursday, August 26, 2010

Up! Personal Portable 3D Printer Review

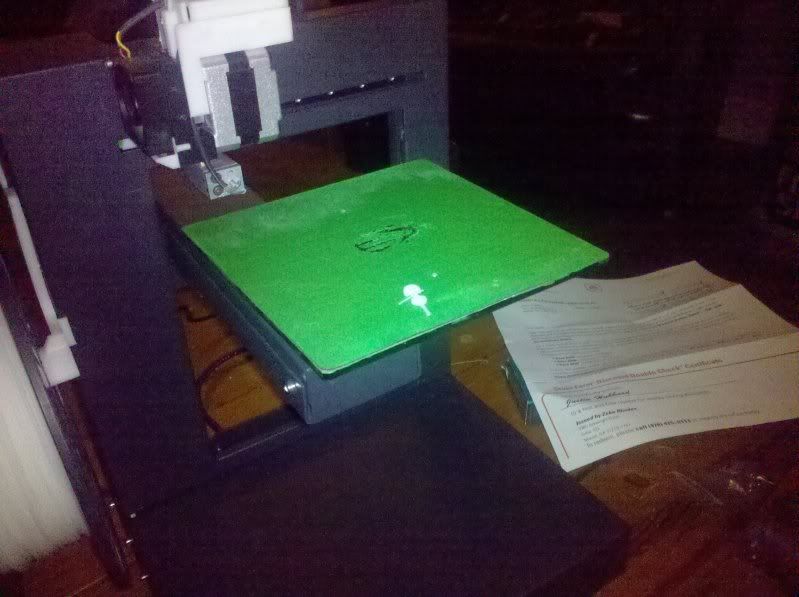

I have been reading about 3D printers for a few years now, but had yet to find anything that was both affordable and hassle free. Professional 3D printers are prohibitively expensive in both materials and actual cost. Home-brew printers while cheap can take a very long time to get operational. Lots and lots of time is spent trying to get the printer to run as it should rather than actually printing. So when a small Chinese company with a website www.pp3dp.com came up with a 3D printer that was affordable, and I didn't have to build it myself, I immediately placed an order. I have to admit that the order process made me a little bit nervous. Because the company was so new, they could only accept direct wire transfer. I decided to go ahead and take a chance. I was either passing a test in optimism or miserably failing a test in patience. Essentially, I was betting that people were good. Luckily (or perhaps typically depending on your point of view) this small unknown company came through in a big way. My printer arrived and even came packed with extras I had not paid for. An extra spool of plastic, extra silicone paint for the heated build platform, and an extra extruder nozzle were among the gifts that I received from the company for my optimism/impatience. They even threw in a year long warranty. Their customer service it very good too. Even though the company is in China, they are quick to respond to questions and concerns.

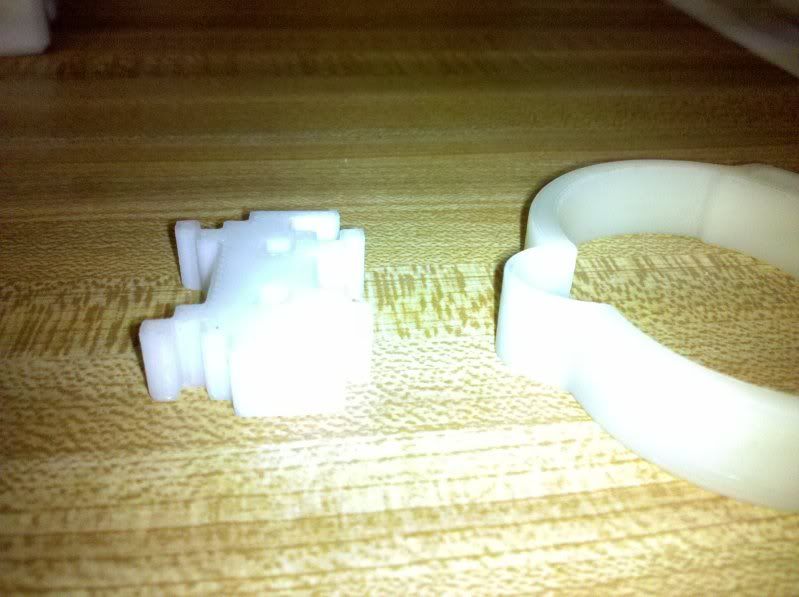

I am sure most of you are not visiting to read about the fine details of me buying the printer, so onto the meat of the review. The printer itself is very well made.(Well mostly well made, It does take three power cords for some reason...) The entire printer is made out of metal with a few plastic parts. The movement is driven via belt and microstepping servos. The z and y axises of movement are handled by a moving platform leaving only one axis of motion for the extruder assembly. This seems to be a well though out design as it removes a lot of the issues cause by the force of the plastic spool pulling against the extruder as it moves about. I was impressed with the minute movements this machine was capable of as well. For instance, when you first get the machine, you have to calibrate it to within .3 millimeters (about the thickness of two sheets of paper). While calibrating it you move the motor by tenths of a millimeter to get it in the sweet spot. This minute movement translates into fantastic resolution in your printed 3D models. When I say fantastic resolution I mean Shapeways, level of detail. I printed out a rep-rap test part to show a little of what I mean.

I am sure most of you are not visiting to read about the fine details of me buying the printer, so onto the meat of the review. The printer itself is very well made.(Well mostly well made, It does take three power cords for some reason...) The entire printer is made out of metal with a few plastic parts. The movement is driven via belt and microstepping servos. The z and y axises of movement are handled by a moving platform leaving only one axis of motion for the extruder assembly. This seems to be a well though out design as it removes a lot of the issues cause by the force of the plastic spool pulling against the extruder as it moves about. I was impressed with the minute movements this machine was capable of as well. For instance, when you first get the machine, you have to calibrate it to within .3 millimeters (about the thickness of two sheets of paper). While calibrating it you move the motor by tenths of a millimeter to get it in the sweet spot. This minute movement translates into fantastic resolution in your printed 3D models. When I say fantastic resolution I mean Shapeways, level of detail. I printed out a rep-rap test part to show a little of what I mean.

The models I printed appeared upon a cursory glance to be smooth (upon closer inspection the layers are visible), but each layer consists of sub-millimeter resolution. Slight sanding produces smooth models. This part really doesnt do the printer justice though as it is designed to be a test part for a printer that doesn't "support" support structures. The built in support structure feature really assists in improving print quality These structures snap off relatively easily and provide support for overhangs in the 3D model.

I say relatively easily because you do have to use a knife on parts, but it is nothing like the rafts used with the Makerbot. The supports are created on the fly automatically and can be adjusted so they are only created for overhangs with angles below a customizable threshold variable. Finally to really lock in their quality, they include a heated build platform and a special silicone paint to adhere the bottom layers of the build to the platform. This prevents curling from when a hot layer of plastic is deposited on a cool layer and warps the cool layer as the hot layer cools and contracts. It is not perfect but it is very close. For really large models it makes a world of difference.

Given the high quality of the prints this printer can create, I would have expected to pay a lot more than my grand total of $1650 dollars. (The printer was $1500. Taxes and shipping were $150). Even the $3000 they will eventually charge once their sale ends seems very reasonable. I know some people would baulk at the idea of paying $3000 for anything but considering this thing can match Solido's promotional parts (Minus the flexibility feature) I consider it a steal.

Subscribe to:

Posts (Atom)